The Miller 70 Series Wire Feeder is a heavy-duty, industrial-grade welding solution designed for seamless wire feeding in demanding environments․ It features a 24V high-torque motor, quick-change drive rolls, and a 3-year warranty, ensuring reliability and efficiency for professional welders․

1․1 Overview of the Miller 70 Series Wire Feeder

The Miller 70 Series Wire Feeder is a robust, industrial-grade welding accessory designed for heavy-duty applications․ It offers a 24V high-torque motor, quick-change drive rolls, and a floating positive drive system for consistent wire feeding․ The feeder features dual tension control, allowing operators to fine-tune wire pressure for optimal performance․ Its durable construction and user-friendly design make it ideal for high-production welding environments․ The system is backed by a 3-year warranty, covering parts and labor, ensuring long-term reliability․ This feeder is compatible with a variety of welding wires and is widely used in manufacturing and industrial settings for its efficiency and dependability․

1․2 Key Features of the Miller 70 Series Wire Feeder

The Miller 70 Series Wire Feeder boasts a range of innovative features for enhanced performance․ It includes a 24V high-torque motor for consistent wire feeding and a solid-state speed control for precise adjustments․ The feeder offers a quick-release drive roll pressure adjustment arm, allowing easy roll changes without losing preload settings․ Its floating positive drive system ensures smooth operation with various wire types․ Additional features include a 10-foot, 14-pin interconnecting cord for compatibility with Miller power sources and a trigger hold function to reduce operator fatigue during long welds․ These features make the Miller 70 Series a reliable choice for industrial welding needs․

Installation and Setup of the Miller 70 Series Wire Feeder

Installation involves unpacking, inspecting, and mounting the feeder securely․ Connect the wire feeder to a compatible Miller power source using the 14-pin cord, ensuring proper electrical connections for safe operation․

2․1 Unpacking and Initial Inspection

Begin by carefully unpacking the Miller 70 Series Wire Feeder from its shipping container․ Inspect the unit for any visible damage or defects․ Verify that all components, including the feeder, 14-pin interconnecting cord, and rubber feet, are included․ Ensure the wire feeder is placed on a stable, flat surface to prevent accidental damage․ Before powering on, check that no welding wire is obstructed or tangled․ Familiarize yourself with the control panel and connections․ If any issues are found during inspection, contact Miller Electric support immediately․ Proper unpacking and inspection ensure safe and efficient operation․

2․2 Mounting and Connecting the Wire Feeder

Mount the Miller 70 Series Wire Feeder on a stable, flat surface using the provided rubber feet to ensure stability․ Avoid placing the feeder where the welding wire could hit any cylinders or obstruct movement; Connect the feeder to your welding power source using the 14-pin interconnecting cord, ensuring it is securely plugged into both the feeder and the power source․ If using a Miller welding gun, attach it via the quick-connect fitting for seamless operation․ Double-check all electrical connections to ensure they match the required voltage specifications․ Proper mounting and connection are essential for safe and efficient operation․ Always follow the manufacturer’s guidelines for installation․

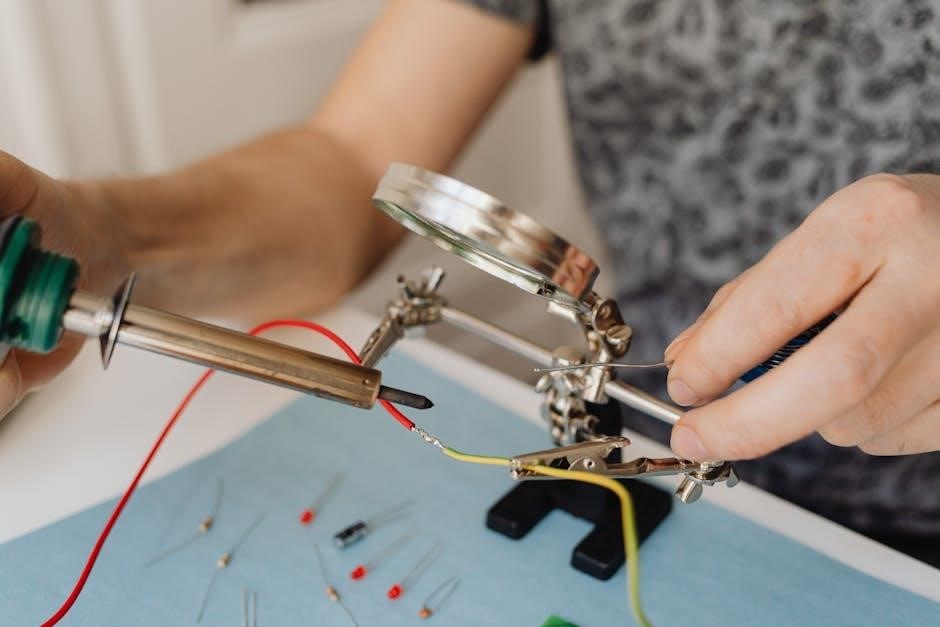

2․3 Setting Up the Wire Feeder for Operation

Begin by selecting the appropriate drive rolls for your welding wire, ensuring compatibility with the wire diameter and type․ Tighten the drive roll pressure adjustment arm to secure the rolls without losing spring preload․ Next, feed the welding wire through the feeder, aligning it correctly to avoid tangling or misfeeding․ Set the wire tension according to the manufacturer’s guidelines, adjusting the dual tension controls for optimal feeding․ Ensure the voltage is set correctly on the power source and verify the wire feed speed using the digital meter if available․ Finally, test the feeder by running a small section of wire to ensure smooth operation․ Always refer to the owner’s manual for specific setup instructions․

Operating Instructions for the Miller 70 Series Wire Feeder

The Miller 70 Series Wire Feeder operates with a 24V high-torque motor, offering precise wire feed control and a trigger hold function for extended welding sessions․ Ensure the wire is properly aligned and tension is adjusted for smooth feeding․ Use the digital meter to monitor and adjust wire feed speed and voltage as needed․ Always refer to the owner’s manual for detailed operational procedures and safety guidelines․

3․1 Turning On and Off the Wire Feeder

To turn on the Miller 70 Series Wire Feeder, locate the power switch, typically found on the front or side panel․ Ensure the wire feeder is properly connected to a 24V DC power source and the welding gun is securely attached․ Press and hold the trigger to test the wire feed mechanism․ For operation, refer to the manual for specific startup procedures․ To turn off, release the trigger, allow the motor to stop, and switch off the power․ Always follow proper shutdown procedures to prevent damage and ensure safety․ Regularly inspect connections and wiring before use․ Proper handling ensures optimal performance and longevity of the equipment․

3․2 Adjusting Wire Feed Speed and Tension

Adjusting the wire feed speed and tension on the Miller 70 Series Wire Feeder is straightforward․ To set the wire feed speed, use the control knob located on the front panel, ensuring it matches your welding requirements․ For tension adjustment, locate the tension knob on the wire feeder and turn it clockwise to increase tension or counterclockwise to decrease it․ Proper tension prevents wire slippage and ensures consistent feeding․ Refer to the manual for specific guidelines tailored to your welding wire type and thickness․ Always test the feed mechanism after adjustments to confirm smooth operation and optimal performance․ Ensure adjustments align with the welder’s power source settings for best results․

3․3 Using the Trigger Hold Function

The Trigger Hold Function on the Miller 70 Series Wire Feeder reduces operator fatigue during long welding tasks․ To activate this feature, press and hold the trigger until the function engages, allowing continuous wire feeding without constant trigger pressure․ This is ideal for extended welds, as it minimizes hand strain․ Ensure the function is disengaged after use by releasing the trigger fully․ Proper use of the Trigger Hold Function enhances productivity and comfort during welding operations․ Always refer to the manual for specific activation procedures and safety guidelines to avoid unintended wire feeding issues․

Maintenance and Troubleshooting

Regular cleaning and lubrication of the wire feeder ensure optimal performance․ Inspect drive rolls and tension springs for wear․ Adjust wire tension and clean the gun liner to resolve feeding issues․ Refer to the manual for detailed troubleshooting steps․

4․1 Regular Maintenance Tasks

Regular maintenance ensures optimal performance and longevity of the Miller 70 Series Wire Feeder․ Clean the drive rolls and wire guide regularly to prevent debris buildup․ Lubricate moving parts, such as the feed roll bearings, every 500 hours of operation․ Inspect the wire liner for damage or wear and replace it annually or as needed․ Check the tension springs and adjust them to maintain proper wire feeding․ Additionally, ensure the feeder is free from dust and moisture․ Refer to the manual for specific lubrication points and maintenance schedules to keep the feeder operating smoothly․

4․2 Troubleshooting Common Issues

Common issues with the Miller 70 Series Wire Feeder include wire slippage, improper arc starts, and motor overheating․ For wire slippage, check and adjust the drive roll tension or replace worn drive rolls․ If arc starts are inconsistent, ensure the run-in control is properly set; Overheating may occur due to excessive use; allow the motor to cool down․ Consult the manual for specific solutions and perform regular maintenance to prevent these issues․ Proper troubleshooting ensures optimal performance and extends the feeder’s lifespan․

4․3 Resetting the Wire Feeder

To reset the Miller 70 Series Wire Feeder, first ensure the power is turned off and the trigger is released․ Disconnect the feeder from the power source, then wait for 10 seconds to allow any residual power to discharge․ Reconnect the feeder and turn it back on․ If issues persist, refer to the manual for specific reset procedures․ Resetting helps resolve minor operational glitches without requiring extensive troubleshooting․ Always follow safety guidelines when performing resets to avoid potential electrical hazards․

Safety Precautions and Guidelines

Always wear protective gear, including gloves and eye protection․ Ensure proper ventilation to avoid fume inhalation․ Keep the wire feeder away from water and flammable materials․

5․1 General Safety Guidelines

Always read and follow the manual carefully before operating the Miller 70 Series Wire Feeder․ Wear protective gloves and eye protection to prevent injury․ Ensure the work area is well-ventilated and free from flammable materials․ Keep children and unauthorized personnel away from the equipment․ Avoid touching electrical components with wet hands to prevent shocks․ Regularly inspect the wire feeder and welding cables for damage or wear․ Properly ground the equipment to prevent electrical hazards․ Never modify the wire feeder without authorization, as this could void the warranty or cause malfunctions․ Follow all safety standards for welding and wire feeding to ensure safe operation․

5․2 Proper Handling of Welding Wire

Handle welding wire carefully to avoid kinks or damage, as this can disrupt feeding․ Store wire in a dry, clean environment, away from direct sunlight and moisture․ Always cut wire cleanly with appropriate tools to prevent fraying․ Ensure the wire spool is securely seated in the feeder to maintain tension․ Avoid over-tightening or under-tightening the drive rolls, as this can cause feeding issues․ Regularly inspect the wire for rust or contamination and replace if necessary․ Use the correct drive roll type for your wire size and material to ensure smooth operation․ Keep the wire feeder clean and free from debris to maintain performance and longevity․

5․3 Electrical Safety Considerations

Ensure the Miller 70 Series Wire Feeder is installed and operated on a dedicated circuit with proper grounding to prevent electrical hazards․ Avoid exposing the unit to water or moisture, as this can lead to electrical shock or malfunction․ Always disconnect the power source before performing maintenance or repairs․ Use only approved cables and connectors to maintain safety standards․ Never bypass or modify safety features, as this can compromise operator safety․ Keep loose clothing and long hair tied back to avoid entanglement with moving parts․ Ensure all electrical components are regularly inspected and replaced if damaged to prevent potential risks․

Warranty and Support Information

The Miller 70 Series Wire Feeder is backed by a 3-year warranty covering parts and labor․ Contact Miller Electric for support or access online manuals and resources․

6․1 Warranty Coverage for the Miller 70 Series Wire Feeder

The Miller 70 Series Wire Feeder is protected by a comprehensive 3-year warranty, covering both parts and labor․ This ensures long-term reliability and performance for industrial applications․ The warranty includes coverage for the Posifeed wire drive system, solid-state electronics, and other critical components․ Miller Electric stands behind the durability and quality of their products, providing peace of mind for professional welders․ For detailed warranty terms, refer to the official manual or contact Miller Electric’s customer support team․

6․2 Contacting Miller Electric for Support

For assistance with the Miller 70 Series Wire Feeder, contact Miller Electric directly through their official website or customer service hotline․ Their support team is available to address technical inquiries, troubleshooting, and warranty-related issues․ Additionally, you can reach out via email or live chat for prompt assistance․ Ensure to have your product’s serial number and detailed issue description ready for faster resolution․ Miller also offers regional support offices worldwide, providing localized assistance․ Their dedicated team of experts is committed to ensuring optimal performance and resolving any challenges efficiently, 24/7․

6․3 Accessing Online Resources and Manuals

Miller Electric provides comprehensive online resources and manuals for the 70 Series Wire Feeder․ Visit their official website and navigate to the support section to download PDF manuals, troubleshooting guides, and technical specifications․ Use the search function to quickly locate the 70 Series resources․ Additionally, access instructional videos and FAQs for optimal usage․ Ensure to verify the authenticity of downloaded materials by cross-referencing with Miller’s official documentation․ This ensures you have the most up-to-date and accurate information for maintaining and operating your wire feeder effectively, 24/7․